Acceptable Quality Level (AQL) is the maximum percent defective (or maximum number of defects per 100 units) that can be considered acceptable. AQL is measured in defects per 100 units.

AQL is used to reduce inspection costs. You only need a small sample to accept or reject a batch of product.

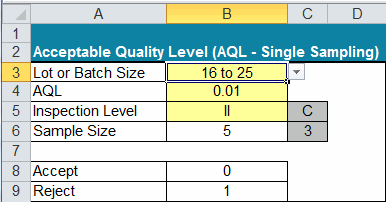

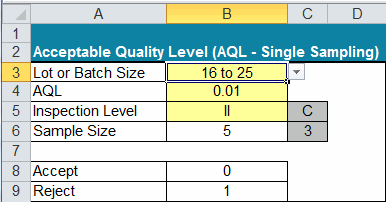

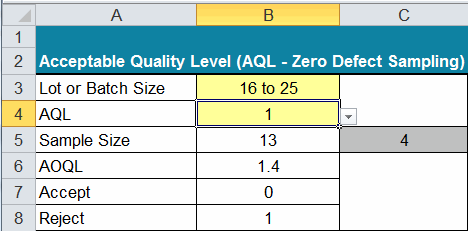

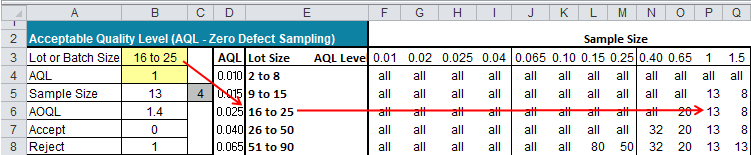

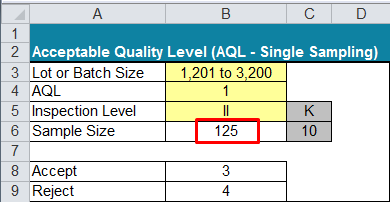

The QI Macros AQL calculator has drop down menus for each variable. Just click on each cell in column B to access the menus.

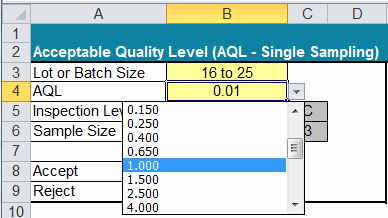

Step 2 - Set the AQL Level (typically 1, but can vary) by clicking on cell B4 and then the pull-down menu.

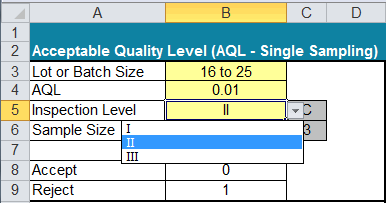

Step 3 - Set the Inspection Level (typically II) in cell B5.

NOTE: ALWAYS use the click-able, drop-down menus when entering your Lot, AQL, and Inspection Level.

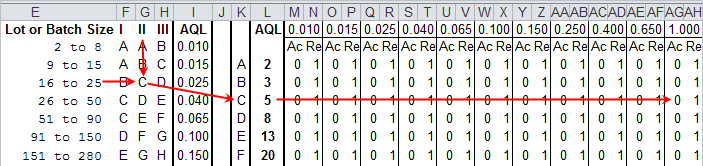

In this example, the template will look up the Sample Size (5) and accept/reject levels (0/1) from the AQL Table. The lot size and inspection level give the letter code "C" which gives a sample size of 5 and accept/reject of 0/1. This means take five samples and if one is defective, reject the lot otherwise accept the lot.

Our reference for the AQL Acceptance Table (Single Sampling) is: MIL-STD-105E.

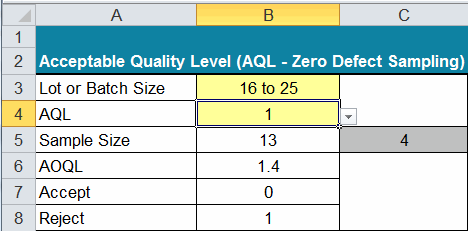

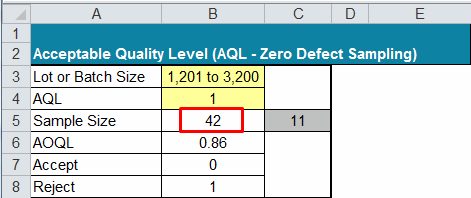

Zero-Based Acceptance Sampling requires that you accept on zero; reject on 1.

There is no other option. It's a different table than the standard AQL Single Sampling table, which might tell you, in some cases, to accept on 2 and reject on 3 defects.

The template will then look up the Sample Size (13), using the AQL level, based on: MIL-STD-1916.

with QI Macros" width="751" height="155" />

with QI Macros" width="751" height="155" />

Note: Zero-based acceptance sampling gives a higher sample size than the AQL Table, but may require fewer samples than AQL sampling.

QI Macros adds a new tab to Excel's menu. To access the AQL tools, click on QI Macros > Calculators > Sample Size Calculator.